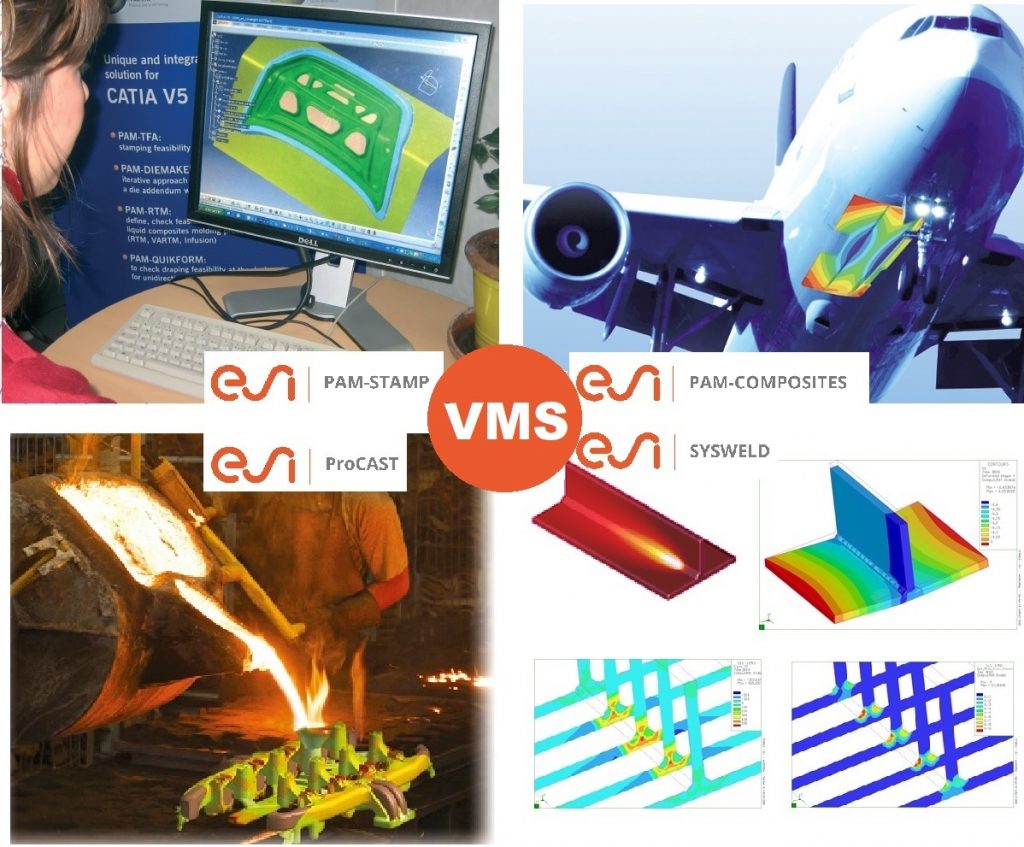

Virtual Manufacturing Suite package embeds:

The core of the Virtual Manufacturing Suite is based on market-tested software packages

In the World of disruptive design changes, Virtual Manufacturing applications span over an ever-increasing range of materials and processes. The portfolio of Virtual Manufacturing in this World encompasses many production methods for validating the manufacturing methods and tooling designs that are planned to produce the parts that make up an approved or released product.

Virtual Manufacturing Suite (VMS) from ESI helps you to:

- Validate materials, processes, product designs for best combination of materials, performance, cost

- Secure feasibility and meet “performance”, “cost” and “allowable” targets at preliminary design phase

- Engineer manufacturing defects and their effects on Durability & Safety

- Influence and affect product design decisions as part of simultaneous engineering

- Validate tooling designs and methods that deliver the approved products. They help you to detail the design of manufacturing process for a designed part including process parameters, tooling, sequencing and inspection

- Identify adjustments that can be made within the constraints of the already approved or constructed tools to assure a launch without triggering new engineering

- Deliver the bill of process with local factory guidelines to meet manufacturing KPIs

- Ensure the dimensional quality of BIW assemblies within allocated cost and time

The VMS from ESI puts all this capability together – It is a suite of solutions that help you to virtually develop and validate key manufacturing and joining processes to fabricate parts, sub-assemblies and assemblies for complex and predominantly light weight engineered objects like a body-in-white, an aero engine or airframe structures, to name a few prominent ones.

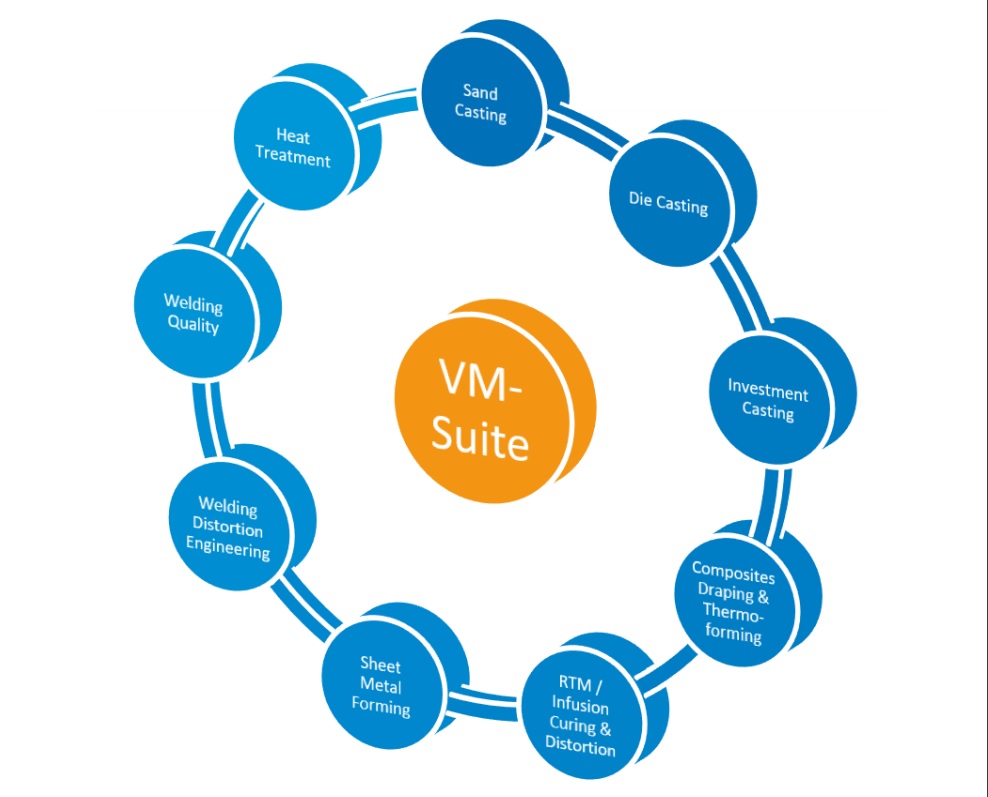

The Virtual Manufacturing Suite (VMS) from ESI offers solutions to the following problem areas:

Modularity of the Virtual Manufacturing Suite

Typical applications – across Industries - covered by the VMS are:

- Sheet Metal Forming of large flexible panels, structural parts, & doors and closures, across Industries, cold, warm & hot formed

- Composites - Light weighting beyond metals covering many different applications in Automotive & Aerospace

- Light Alloys premium quality castings for body work, combustion engines, conventional power trains and electric drive systems

- High temperature / special metal premium quality castings in Aerospace

- Cast Iron & Steel premium quality castings in Energy, Heavy Industry & Machinery

- Weld Quality & Assembly Distortion Engineering to fabricate sub-assemblies and assemblies, across Industries

Process families covered by the VMS from ESI are:

- Sand Casting

- Die Casting

- Investment Casting

- Investment Casting

Ready for a license?

Looking for more information?